Authoritative argument: F-20 fighter engine comparable to the world's aviation top three

World-class Chinese military, and is expected to compete with the U.S., Britain, France for a new generation of aviation engine Laurel.

What is the flying hair integration? Is the integration of the flight control and engine control, simply achieve pilots no concerns about the operation, the operation of the pilot through telex flight control software to achieve the operation of the pilot intent, and in response to this action requires pilots in addition to the wing surface there vector thrust.

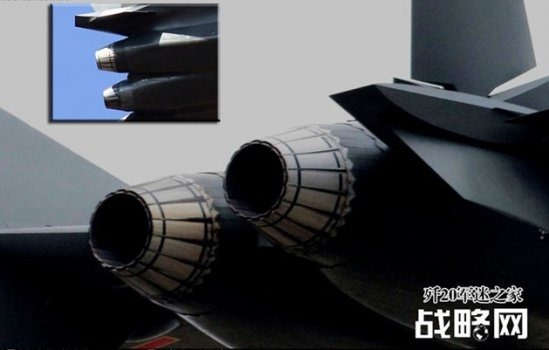

Vectored thrust apparently has been considered in the design of the flight control system, otherwise how integration? At the same time confirmed the engine is vectored thrust engine Xuyong Ling also said earlier in the article and T50 in the first flight did not use vectored thrust engine T50 is a great pity, the T50 test flight has been more than 40 times, and did not use vectored thrust engines reports, it seems that The Westerner is true die.

Four generations of the maiden flight of the engine is the domestic vector thrust engine, the significance of how estimates are not large!

Too much to force it!

Metallurgy and materials scientists Shi Changxu his outstanding contributions to research and development of high performance fighter, the State Supreme Science and Technology Award.

According to scientists in Mainland China aircraft engines, a former director of the division of the Institute of Metal Research, Chinese Academy of Sciences professors developed several series of top-secret heat-resistant alloys.

These alloys developed decades ago, just takes a long time to test the test because metallic materials used in aircraft engines, until recently, the division developed by Professor alloy materials for China-made aircraft engine began.

1955, Shi Changxu farewell to his coaching post at the Massachusetts Institute of Technology embarked on a journey to return. He is the U.S. government banned more than 30 Chinese-American scientists to return to their socialist motherland. He and Qian Xuesen almost the same period to leave the United States, Qian Xuesen Caltech rocket experts, who later became the founder of the Chinese aerospace industry.

Shi Changxu arrived in Shanghai, was immediately assigned to Shenyang, where the heavy industrial base of Liaoning Province in northeast China, aims to increase steel production. Later, the relationship between Beijing and Moscow deteriorated rapidly, the Russians no longer help their old ally developed fighter. Chinese military turned to Shi Changxu other scientists.

With diligence, talent and luck, Shi Changxu not only using the traditional methods he learned in Western countries manufacturing the alloy, but also invented some new alloy series.

F-20 facelift of new phased array radar test flight

F-20 facelift of new phased array radar test flight

These newly developed alloys in laboratory tests the performance is quite good, and that no one dared to use them. For security reasons, aircraft designers have followed the traditional alloy manufacturing large-scale production of the fighter engine in China, and its performance is seriously lagging behind similar products abroad.

Since then, the the alloy series developed by Shi Changxu began to accept recognition of the long journey in the industrial field. Until recently, because of their alloys used in -20 F and other state-of-the-art fighter before get fully recognized designers.

Materials Science and Engineering, Shanghai Jiaotong University, said Professor Zhang Lanting, the highest honor for China aviation field of materials science, the long-awaited. Professor Zhang pointed out, some people think that China does not have the material for the manufacture of high-performance aircraft engines, but they are wrong. Professor Zhang said, in fact, we have many of the most superior quality materials, but to aircraft design staff to convince these materials, we have decades of testing must be carried out - usually 30 years - in order to guarantee the absolute security. In the next 10 years, the Chinese-made engine will begin to replace the imported engines in civilian areas. In the military field, the work has begun to replace imports with domestic engine.

Aviation's highest institution of Beijing University of Aeronautics and Astronautics new materials science experts pointed out that China is rapidly closing the technology gap between the world-class engine manufacturers. With the successful test flight of the F -20 fighter and other new aircraft, now really is the time to reward these unsung heroes.

Said the F-20 SU-27, even more than the United States F22, which is an indisputable fact. Takeoff weight of over 35 tons of data with U.S. military experts can be estimated, it is not boastful be bluffing. Such a large body with existing engine (J-10 or J-11) seems unlikely that a so-called Russian-supplied, that is nonsense, because China did not import more than four generations of machines engine, it is apparent that China four generations of machines supporting 18 tons of thrust WS-15 Taihang engine successfully developed, is no longer necessary to debate.

Judging from the first flight engine sound absolutely new type of high bypass ratio engine, the bypass ratio more than F-10, SU-27 and F-22 three fighters. Circulated video shows the "F-20" take-off process, from which to see the take-off and did not see the the engine tail of Spitfire, which is enough to show that China "F-20" the engine vents infrared stealth technology has reached world-class. Data show that F - 22 use the same state-of-the-art infrared stealth technology, the by jet cooling rectangular vents, vertical tail, horizontal tail, the tail brace extends back can be obscured to the engine vents infrared radiation. Before the hot jet flying out of the tail vents on cooling, and thus significantly reduce the infrared signature. The F-20 engine nozzle could be so perfect, a lot of foreign armies expert after watching that incredible.

The engine of the F-20 with WS-15 high-thrust engine! This has no doubt skeptical, but outside the engine performance, including noise, the largest number from the United States, in American eyes, China should accomplish anything fishes, alone, China behind closed doors to develop the latest generation of aero-engine is simply is a fairy tale. Is this right, this can only say that Americans are arrogant accustomed, to be the most popular is the misjudgment of the United States has been the formation of its patent, no need to argue.

I think that China is fully capable of aero-engine manufacturing better than the United States. As early as 2009 a military Archive had literally leaked message successfully developed China's high thrust-to-weight ratio turbofan engine core machine, which made a thrust vectoring technology industry's argument. 09 at the end of a science and technology magazine article entitled "China's aviation engine was a breakthrough, thrust to weight ratio is the substantial increase in articles, Metals and Materials, Beijing University of Science and Technology, State Key Laboratory said that with China's independent intellectual property rights of a new generation of aviation aerospace engine materials, high-temperature high-performance high niobium titanium aluminum alloy material will enter a stage of industrialization. The new high-temperature high-performance high niobium titanium aluminum alloy can further improve the the turbofan blades of high temperature capability, allowing improved engine inlet temperature, thus increasing engine thrust.

High temperature alloys, nickel-based high temperature materials used in modern Western countries and China developed a new type of high-temperature high-performance high the niobium titanium-aluminum alloy, high temperature density than nickel-based superalloy half. This technology will enable the Chinese aerospace engine materials world leader, According to reports, the application of high the niobium titanium-aluminum alloy, has opened a new development of the aviation, aerospace, automotive, and other important areas of existing equipment to get the breakthrough. More critical is that, due to the high the niobium titanium-aluminum alloy density is about half of the nickel-based alloys, and use it to manufacture the engine hot parts, can greatly reduce the weight of the engine, which greatly increased the engine thrust-to-weight ratio.

March last year, a newspaper published a report entitled "China's most advanced military aircraft engines trial has delivered 2 units. The article says, the young design team by the automatic control of the company by four rooms from development and production to the successful delivery of user domestic technology the most advanced, most complex function a key model products, articles last sentence of the exciting Chinese aviation engine decision It does not drag the hind legs of the four generations of machines in China. To be sure, this F-20 engine is it.

F-20 flight test in the case of the highly anticipated, indicating that the engine designers have been full of self-confidence, and this confidence will become a guarantee of four generations fitted out ahead of the Chinese Air Force, I believe that the F-20 flight test has been obtained great harvest of data, as well as China's new generation fighter aircraft and aero-engine and lay a solid imprint, proved to the world, the Chinese military is a world-class, and is expected to compete with U.S. and British law for a new generation of aero-engine Laurel.

The strategic bomber shown on Popular Science looks like the model shown on CCTV.PS said The bomber used Wang Zhengou turbo-scam jet engine and maybe Shou-En Zhu grapheme air frame.

ReplyDelete